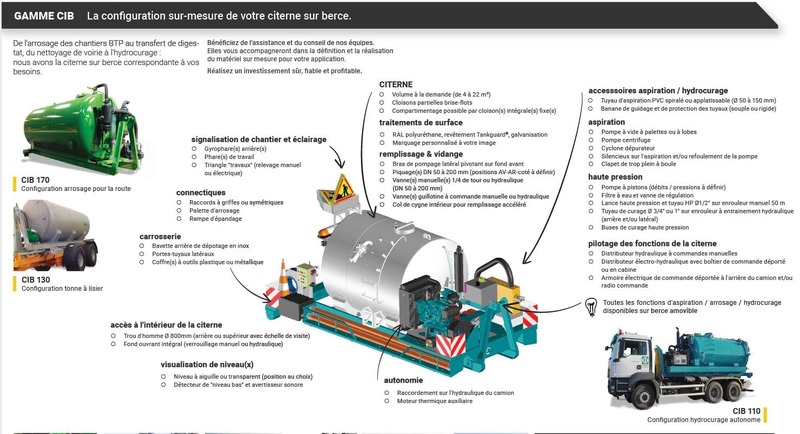

Depending on your application, equip your tank with the appropriate suction, discharge and drive components:

- Vacuum pump

The vacuum pump allows you to vary the volume inside the tank in order to suck up or discharge material. Gourdon recommends two types:

Vane pump

- Suitable for watering and spreading tanks

- Economical

- Flow rate from 7,200 l/min to 53,000 l/min

- Vacuum level: 60% to 80% continuously

- Cooled by air or water injection

- Paddle lubrication by oil injection

Lobe pump

- Suitable for intensive use such as hydrocleaning

- Vacuum flow rate: 21,000 l/min to 181,000 l/min

- High vacuum level: 93% continuous

- Low wear

- Air-cooled

Vacuum pumps are generally equipped with a vacuum line: a cyclone purifier, a silencer on the suction and/or discharge side of the pump, a ball overflow valve, a vacuum valve and a pressure relief valve.

- High-pressure pump

The high-pressure pump allows water to be delivered at high pressure for intensive cleaning work. Gourdon recommends one variant:

High-pressure pump

- Piston pump (flow rates/pressures to be defined)

- Water filter and control valve

This equipment comes with accessories such as a high-pressure lance, HP hoses (Ø1/2″ on a 50 m manual reel or Ø1″ on a hydraulically driven reel) and high-pressure cleaning nozzles.

- Internal combustion engine

The combustion engine allows you to use your tank on a cradle independently, whether it is located on the chassis of the lorry/trailer or “on the ground” in a fixed position. This equipment comes with the usual accessories for a combustion engine, such as filters, coolers, tank, etc. The brand and power (kW) of the engine will be determined in conjunction with Gourdon according to your application.