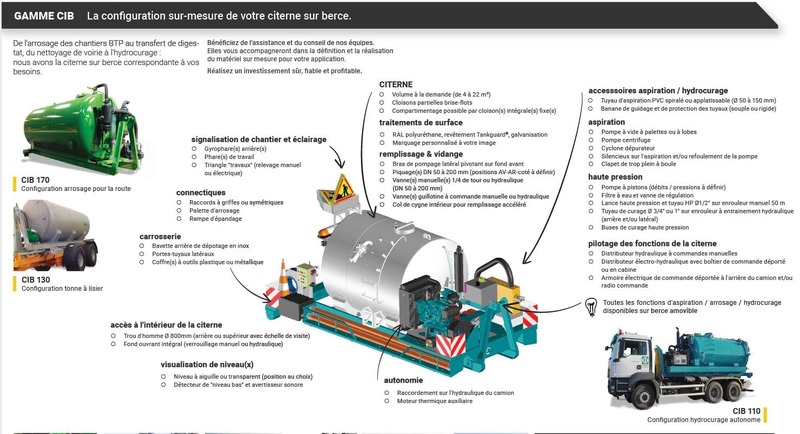

Gourdon truck-mounted tanks are specially designed to meet high productivity requirements in urban, on-site or extreme conditions. This equipment combines a motorised vehicle with a tank body to provide drivers with the best working conditions and enable them to carry out their work efficiently.

Applications:

- Watering public works sites: limiting dust and environmental pollution during construction or quarry work.

- Hydrocleaning: draining pits and cleaning networks and pipes.

- Hazardous materials: ADR-approved equipment for the transport of hazardous materials.

***********************************************

Gourdon offers you its expertise and advice in defining your project.

How to configure your tanker truck?

1. Define the application of the equipment according to your activity.

2. Define the characteristics of the carrier chassis vehicle:

- 4×2 wheel drive lorry (GVW 19T)

- 6×2 – 6×4 wheel drive lorry (GVW 26 tonnes)

- 8×4 wheel drive lorry (GVW 32T)

- Articulated construction tipper

- Other vehicles

Motorised vehicles are supplied by Gourdon’s partner manufacturers (new equipment) or are existing vehicles from our customers’ fleets (equipment to be modified).

3. Define the characteristics of your tank body:

- Volume on demand (from 4 to 22 m³)

- Partial wave-breaking partitions

- Compartmentalisation possible with fixed integral bulkhead(s)

- Surface treatment: RAL polyurethane, Tankguard® coating, galvanisation

- Customised branding to reflect your image

- Stainless steel rear unloading flap

- Side hose holders

- Plastic or metal tool box(es)

- Underride guard

- Side cyclist guards

4. Define the drive system for your tanker:

- Vacuum pump for suction/discharge (see options)

- Connection to truck equipment (auxiliary power take-off, full power take-off)

- Combustion engine for autonomous drive (see options)

- High-pressure pump for hydrocleaning application (see options)

5. Define the control of your tank’s functions:

- Hydraulic distributor with manual controls

- Electro-hydraulic distributor with remote control box or in the cab

- Remote electrical control cabinet at the rear of the lorry and/or radio control

6. Define the filling and emptying connections:

- Fixed or tipping tank with tipping cylinder

- Water cannon

- Side pumping arm pivoting on front base

- DN 50 to 200 mm connection(s) (front, rear and side positions to be defined)

- Upper filling cone (gravity filling)

- Manual quarter-turn or hydraulic valve(s) (DN 50 to 200 mm)

- Manually or hydraulically operated guillotine valve(s)

- Internal gooseneck for accelerated filling

- Claw or symmetrical connections

- Sprinkler blade

- Spreading ramp

7. Equip the equipment to carry out inspection and maintenance operations:

- Manhole Ø 800 mm (rear or top with inspection ladder)

- Fully opening bottom (manual or hydraulic locking)

- Spirit level or transparent level (position of your choice)

- Porthole

- Low level detector and audible alarm

8. Equip the equipment with the accessories necessary for productive, comfortable and safe work:

- Spiral or flattenable PVC suction hose (Ø 50 to 150 mm)

- Hose guide and protection (flexible or rigid)

- Rear rotating beacon(s)

- Work light(s)

- Warning triangle (manual or electric)

- Hydraulic or manual hose reels (hydrocleaning)

- Cleaning nozzles and high-pressure lance (hydrocleaning)

The CIM range of truck-mounted tanks are DREAL approved. The equipment is fitted in accordance with regulations and the vehicle is approved by an authorised inspection body.

Information: Truck-mounted tanks are available in ADR versions for the transport of hazardous materials (hydrocleaning on industrial sites, transport of hydrocarbons, etc.).